The latest in precision application technology

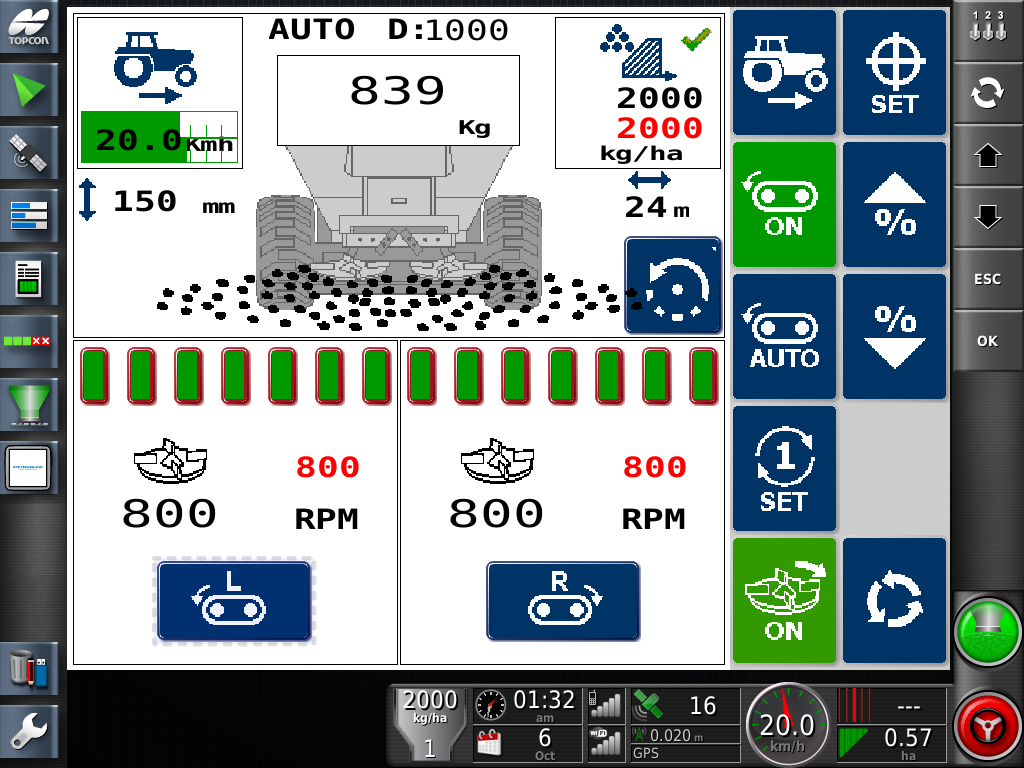

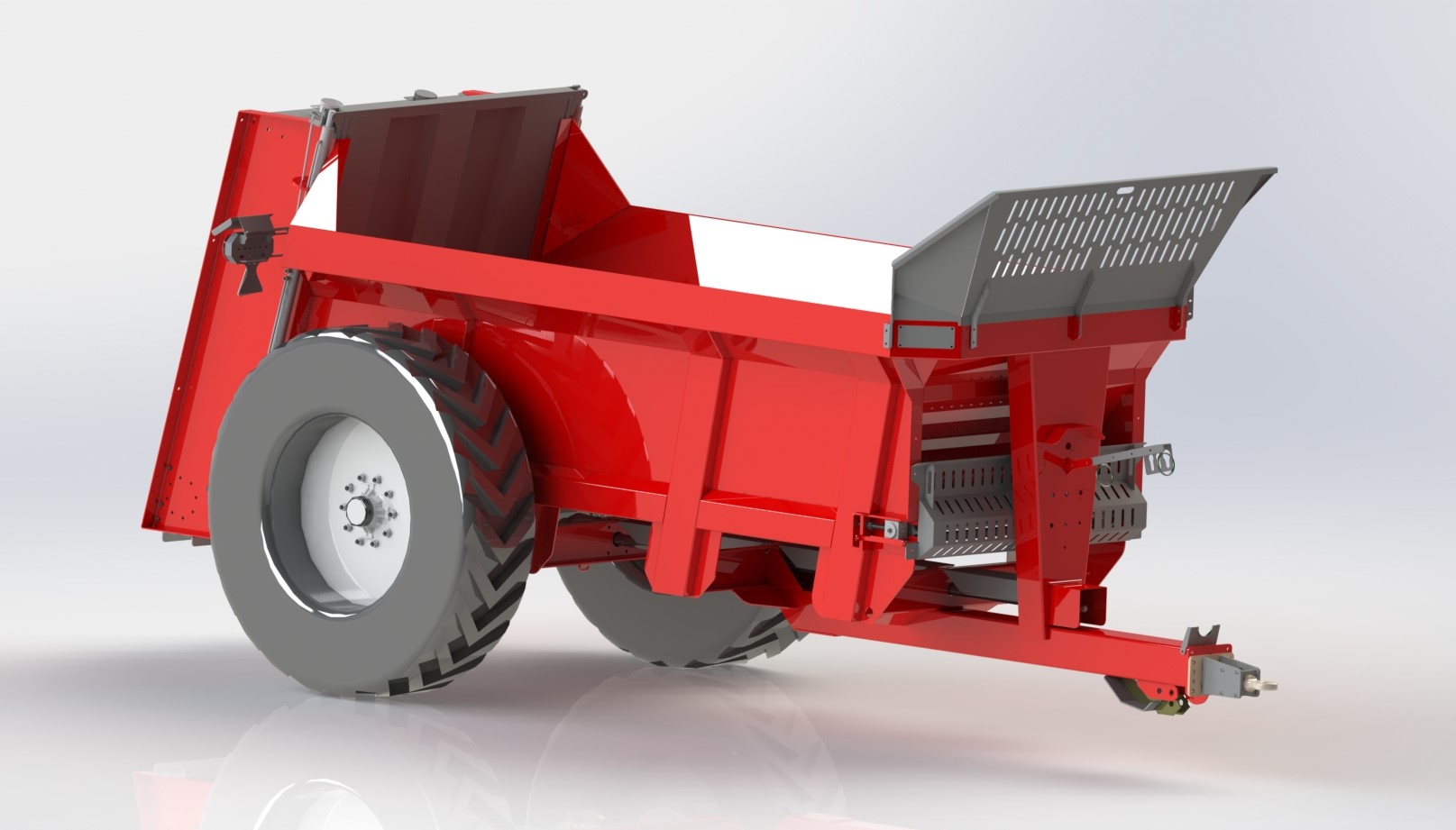

- The Agri-Spread section control spreader use two independent, hydraulically controlled conveyors via GPS, to feed material onto Independently controlled hydraulic spinners to give the applicator the most precise distribution of product where required.

- The twin conveyor system gives the spreader the ability to change the rate on either side of the machine in relation to the spread width/rate required. In conjunction to this, the spinner speed automatically changes speed to match the width required based on the amount of sections turned off.

- As well as automatic section control, the operator can shut off one side of the spreader by the touch of a button. Boundary or headland spreading is also a one-touch operation to reduce the spread width on one side only.

- In addition to the twin conveyor, Agri-Spread have also incorporated the latest advancements in belt conveyor systems – Positive Drive – to produce the most precision built spreader on the market