INTRODUCING A NEW GENERATION OF SPREADER

The Latest Agri-Spread AS2000 series is an advanced precision spreader, which takes simplicity, durability, capacity and accuracy to the next level

- Whether you are spreading fertiliser, lime, gypsum or manure, the AS2000 series precision Agri-Spread delivers the target rate at the highest level of accuracy. The new AS2000 series is

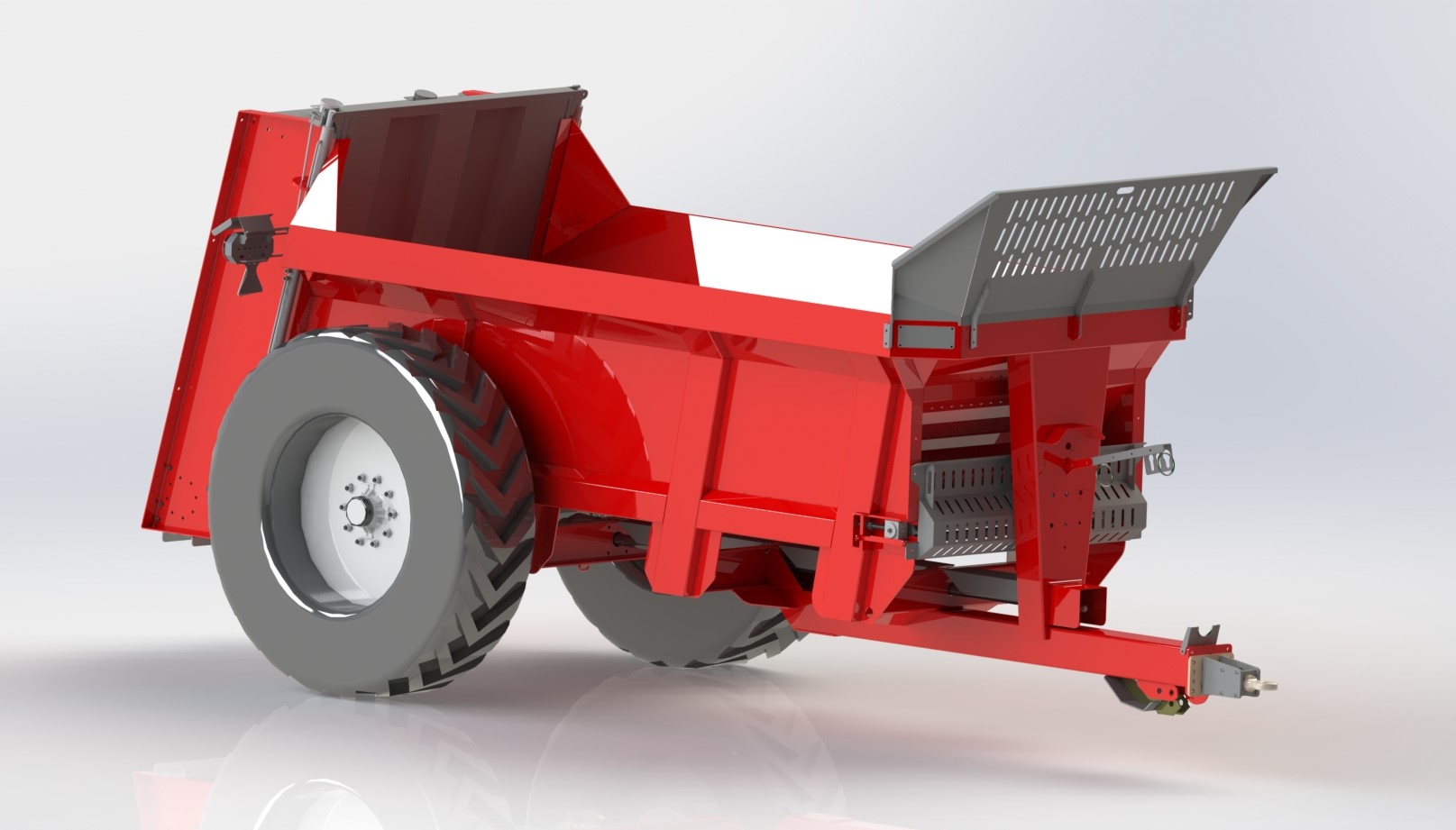

independently certified to spread fertiliser to 36m and lime to 12m. It’s built to last, functional in design and is easier than ever to operate. - New design features include the Agri-Spread exclusive Positive Drive Conveyor System, making it virtually impossible for the conveyor to slip. A redesigned hopper featuring more stainless components and a new adjustable rear deck spinner system to ensure the highest level of accuracy and distribution of all products are some other new features visible on the AS2000 series.

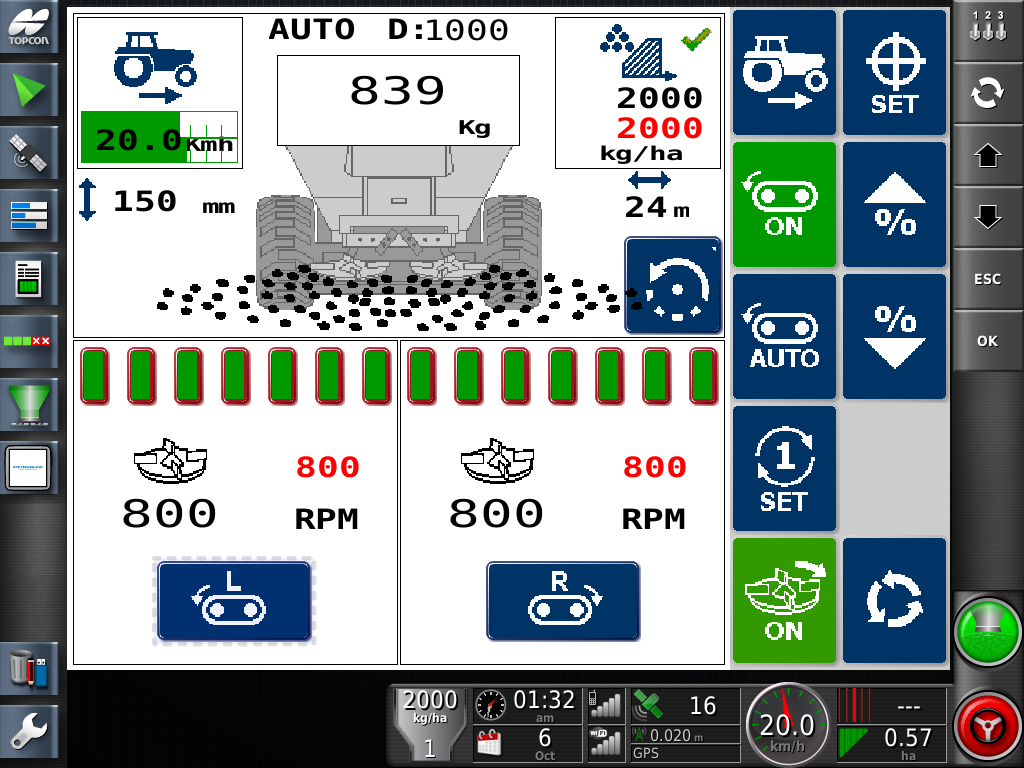

- The AS2000 series takes care of variable rates using mapping technology and can accurately apply product with variable bulk density using dynamic auto calibration. Four load cells and a variable speed floor belt guarantees the target rate regardless of forward speed.

- Reducing input costs by minimising overlap, Agri-Spread are also excited to announce the release of optional Section Control available throughout the whole AS2000 series range. Taking care of the required spread width in 14 sections, working in conjunction with field shape and GPS map data alongside the already popular auto shut off for headlands and border control functions spreading is easily managed from the Agri-Spread VT controller meaning little to no overlap. And most importantly a reduction in fertiliser requirements from 5-15%.

- ISOBUS / VT compatible the Agri-Spread provides control of the spreader as well as recording input application data for farm management documentation from inside the cab.

- ISOBUS AEF Certified

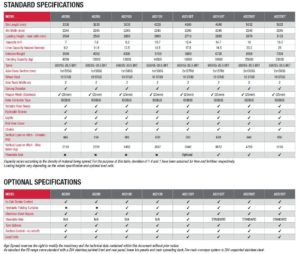

- A significant development within the AS2000 series range is the introduction of two new additional models, providing even more capacity than ever before

CONSISTENTLY EVOLVING & IMPROVING DESIGN FEATURES

- As the leaders in spreading the Agri-Spread team are focused on developing their product to meet customers’ changing needs. The enhancements that are offered with the new AS2000 series encompass the need for capacity and simplicity whilst retaining the earned reputation of accuracy and durability.

Load sense Hydraulics

- The AS2000 Hydraulic Valve Assembly is compatible with tractors using load sensing hydraulics. The Disc spinners and belt drive(s) now independently control their hydraulic oil requirement. The new hydraulic valve assembly is standard on the new 2000 series and can be operated as a fixed pump for non load-sensing tractors.

Hopper & Chassis

- The 2000 series is released with a redesigned bin hopper shape with formed last laser cuts and folds to prevent material build up. The front panel is now completely fabricated with stainless

steel along with the rear and the bottom third of the bin and full fabrication of extensions. Other new features include adjustable hitch options, two sight inspection windows and a swinging hydraulic hose holder. Stainless steel pressure and return lines are fitted to minimise oil temperatures, increase longevity and reduce maintenance. All other cabling is now encased inside the chassis rails to avoid cable erosion, corrosion or damage.

Spreading Deck System & Spinner Vane Design

- The AS2000 series comes with a completely new Spreading deck system with adjustable rear deck positioning. The spread width can be fine-tuned by adjusting the deck forward and back. Users can set spread bout width with the deck and pattern distribution with vanes. The new two vane spinner design, one long and one short, creates an accurate and adjustable placement of product across the spread width. With the development of more fertiliser products options and blends the moving deck gives more options for settings to adjust for maximising accuracy and placement.

Capacity

- One of the developments of the AS2000 series is the introduction of two new models to the range. The AS2200 and the AS2220 providing even more capacity and productivity than ever before. Coupled with the durable Agri-Spread chassis system and a steerable axle, provides the consistent flotation that the Agri-Spread tandem range is renowned for.

Accuracy

- Independently accredited to spread fertiliser up to 36m and Lime to 12mtr

- Two sets of discs; one for fertiliser and one for lime, gypsum and manure

- Applies variable bulk density products with precision and control using dynamic weighing

- Adjustable rear spinner deck and vane position to ensure an even spread regardless of product

- Agri-Spread International makes no warranty, representation or guarantee regarding the suitability of its machine products to discharge and spread all possible fertilisers, manures, lime types, gypsum types, bio-sul types and other bulk product materials especially due to complex factors such as storage, moisture, humidity, bulk density, particle size, particle shape, friction, cumulative strength, interlocking, cohesion, ratholing and bridging etc.

- Twin belt section control spreaders are not recommended for lime, gypsum, bio-sul or any non-flowable materials and products.

- Agri-Spread reserves the right to modify or change designs, features, functionality, options & other product specifications without notice or obligation.